CASE STORY

KALL Ingredients Heatcube

A long duration thermal energy storage project in Hungary

On November 23rd, 2023, Kyoto, along with financial partner Kyotherm and energy trading partner in Hungary, Energiabörze Kft, signed a commercial agreement for delivering Heat-as-a-Service (HaaS) to the Hungarian food ingredient producer KALL Ingredients Kft.

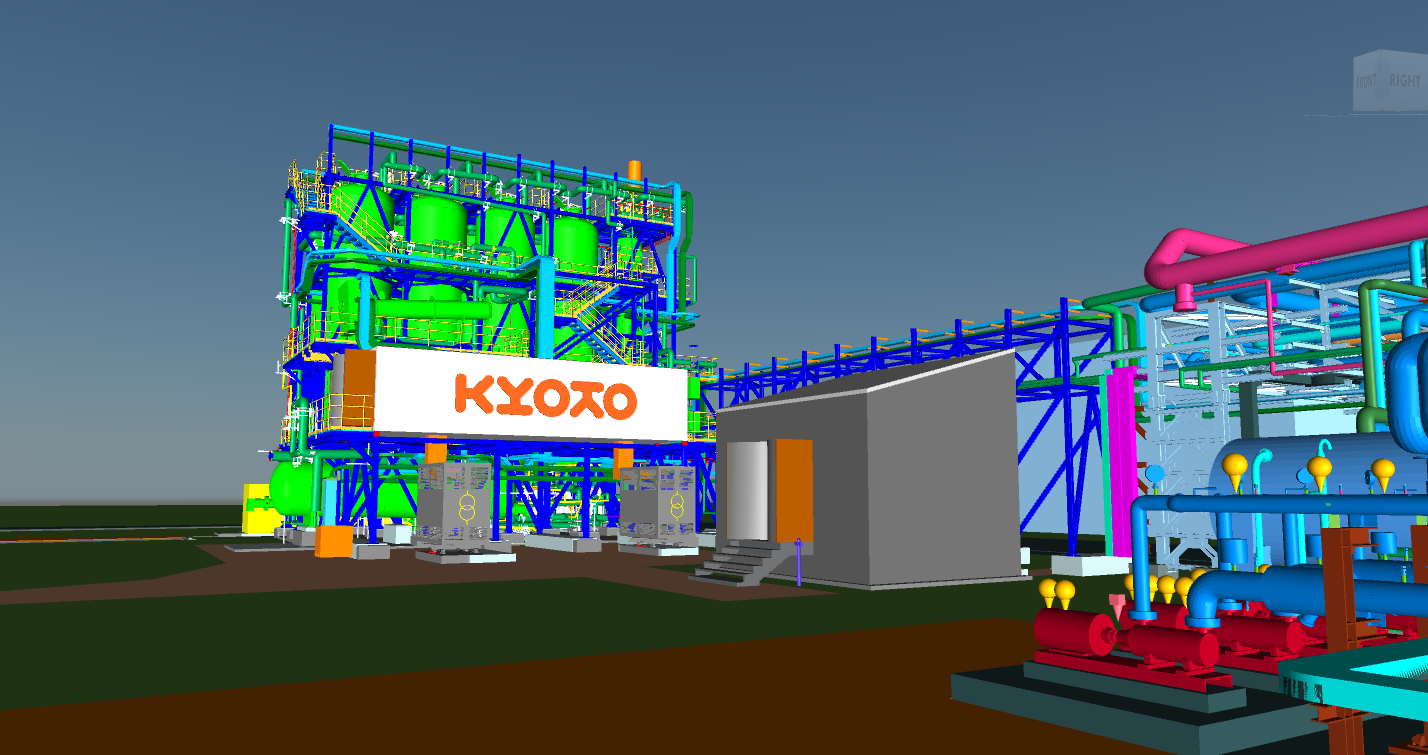

Heatcube at KALL Ingredients will be Kyoto’s second generation Heatcube, with a round-trip-efficiency of 93%, a rapid ramp-up and decoupled charge & discharge, designed to also serve as a flexible asset for the grid, and the digital DataOps platform supporting the operations & maintenance of Heatcube.

KALL Ingredient’s Heatcube will replace the existing natural gas supply and is designed with 56 MWh of storage capacity, offering an annual capacity of more than 30 GWh.

This will result in a CO2 reduction of up to 8,000 tons annually. This Heatcube will function as an asset in the flexibility markets and utilize intermittent renewable energy whenever available, while supplying a constant flow of steam for KALL’s industrial production.

Keep scrolling to discover all the exciting progress we've made so far!

CAPTION: In April 2024, the concrete foundation was set for Heatcube installation.

CAPTION: In April 2024, the concrete foundation was set for Heatcube installation.

CAPTION: In July 2024, the tanks, steam generator and boiler were installed.

CAPTION: In July 2024, the tanks, steam generator and boiler were installed.

Manufactured in Europe

The thermal battery was manufactured in Europe.

Custom Configuration

KALL Ingredient’s Heatcube is configured with 56 MWh of storage capacity and with a discharge load of 7 MW.

Electrical energy

Electricity sourced from the grid including utilizing intermittent renewable energy whenever available.

The Contract

Heatcube with a Heat-as-a-Service (HaaS) agreement with KALL Ingredients.

The core of this project lies in Hungary’s reserve market, where the flexibility of our Heatcube technology enables us to supply steam at exceptionally competitive prices. This goes beyond just providing heat; it's about setting a new standard for industrial energy efficiency and sustainability.

With a storage capacity of 56 MWh and annual capacity of 30 GWh, Heatcube at KALL Ingredients will replace the supply of natural gas currently in place. With this Heatcube, a CO2 reduction of up to 8,000 tons annually is ensured.

Heart of molten-salt

During operation, high-temperature molten salt flows into well-insulated thermal storage tanks, where it remains in a liquid state throughout the plant's operating cycle. The molten salt is then directed to a heat exchanger, where it is heated using electricity during the charging phase. Once fully charged, the hot molten salt is transferred to a steam generator, producing steam that is delivered to KALL Ingredients for use in food manufacturing processes.

Molten salts are an ideal medium for thermal energy storage, possessing high volumetric heat capacities. This means they can store a substantial amount of heat while occupying minimal physical space, making them easy to transport. Furthermore, being a mature and commercially proven technology, they are also cost-efficient and competitive with today's energy prices.

Kyoto Group champions molten salts for Heatcube, valuing their ability to store and deliver heat reliably and cost-effectively, with superior heat capacity making them the ideal choice.

Our partners

This project has been made possible through our collaboration with KALL Ingredients Ltd, a leading corn-processing facility in Europe located in Hungary. Our financial partner, Kyotherm, and our energy trading partner in Hungary, Energiabörze Kft, have played a crucial role in bringing this project to fruition.

Through Kyoto’s innovative Heat-as-a-Service (HaaS) solution, we will together facilitate sustainable industrial energy solutions.

CAPTION: In October 2024, 95% of engineering was finalized and the structural framework in place.

“Our aim is to rely entirely on sustainable energy in the future while ensuring lower energy costs. Kyoto’s Heatcube will provide us with a stable and cost-effective supply of sustainable process heat, and we are excited to get started with this project.”

Ádám Sass, Strategic Director of KALL Ingredients Kft.

-

-

-

APRIL 2024

READY TO BUILD

The concrete foundation is laid and ready for Heatcube’s steel structure. -

JUNE - AUGUST 2024

FROM STRUCTURE TO SYSTEM!

The steel structure was erected, followed by installation of the boiler, steam generator, and tanks. Eight molten salt tanks and Heatcube’s upper heater were installed, and key electrical systems, including the auxiliary transformer and Battery Management System, arrived on site. -

NOVEMBER 2024

PROGRESS IS STEAMING AHEAD!

E-tracing cable installation for the Molten Salt Tanks has begun and secondary pipe supports, cable trays, and scaffolding are successfully installed. -

JANUARY - MARCH 2025

MECHANICAL MILESTONES

Main mechanical components were installed, with focus on molten salt and water-steam piping. Electrical and instrumentation works progressed in parallel, alongside insulation and cladding of the molten salt storage tanks. By March, mechanical works were nearing completion and the first hydrotesting of the molten salt piping was completed. -

APRIL - JUNE 2025

COMMISIONING PROGRESS

Mechanical completion moved into its final stage, with system reinstatement, testing, and insulation completed. As installation wrapped up, salt deliveries began and pre-commissioning activities started. By June, the project entered full commissioning, with mechanical, electrical, and I&C work completed and the solids handling unit operational. -

OCTOBER 2025

EUROPE'S LARGEST THERMAL ENERGY STORAGE UNIT INAUGURATED

“Sustainability is central to our operations. Kyoto’s Heatcube offers a stable and cost-effective supply of clean process heat, helping us reduce energy costs and move towards full reliance on renewable energy,” said Maarten Welten, Managing director of KALL Ingredients..

/01%20Homepage/1.6%20Partners%20logos/KTH@2x.png)

/01%20Homepage/1.6%20Partners%20logos/KALL%20Ingredients_grey.png)

/01%20Homepage/1.6%20Partners%20logos/Kyotherm_300.png)

/01%20Homepage/1.6%20Partners%20logos/Vulcanic.jpg)

/01%20Homepage/1.6%20Partners%20logos/Cognite_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/RPOW@2x.png)

/01%20Homepage/1.6%20Partners%20logos/Energiaborze_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/steinmueller_engineering_company_logo_300.png)

/01%20Homepage/1.6%20Partners%20logos/Yara@2x.png)

.jpg)