What is it?

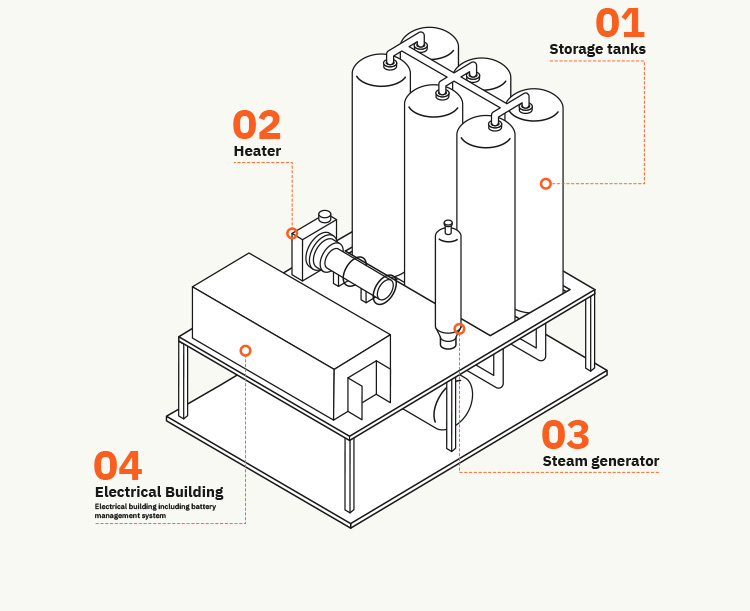

Heatcube is a thermal battery (or Thermal Energy Storage system) that stores energy in the form of high-temperature heat, rather than electricity. It supplies on-demand heat for industrial processes, offering a flexible, low-carbon alternative to fossil-fueled boilers.

How does it work?

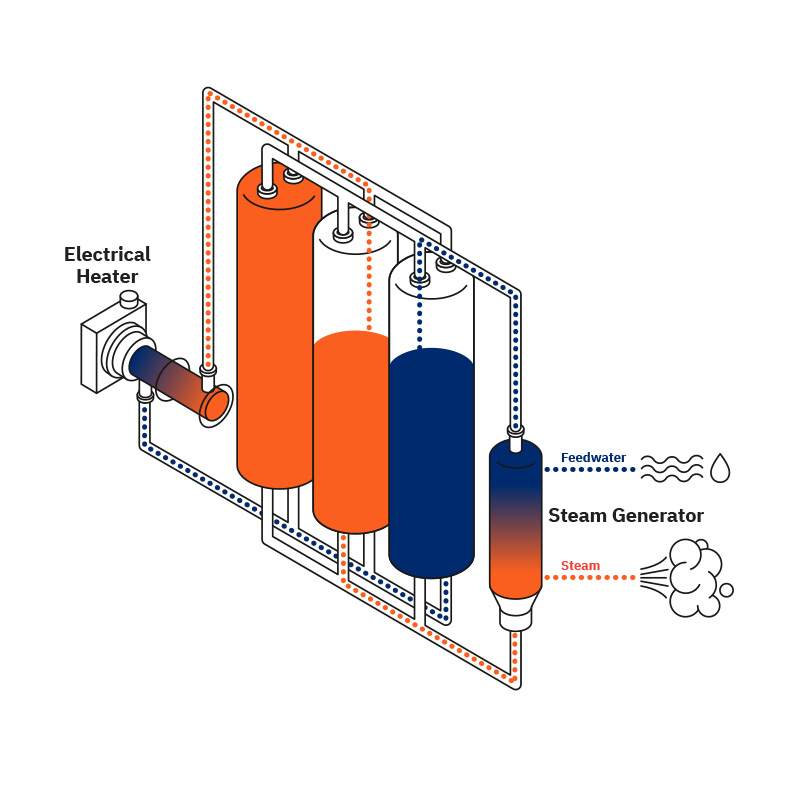

Heatcube's technology uses resistive heaters to convert low-cost electricity into heat with 93% efficiency. That heat is stored in molten-salt and released as process heat — whenever your operations need it.

Charge with molten-salt

Why molten salt?

As a liquid, molten salt has a high volumetric capacity. It can hold a lot of heat, without taking up too much space. And it can do so without the risk and cost associated with highly pressurized steam vessels, while being non-flammable and non-toxic.

Commercially proven

Molten salt is the most mature solution for high-temperature Thermal Energy Storage. Unlike latent or thermochemical alternatives, sensible heat storage with molten salt is a commercially proven and widely adopted approach for storing heat at scale

Flexible heat delivery

Simultaneous charge & discharge

Heatcube enables simultaneous charging and discharging, a capability few Thermal Energy Storage systems offer.

Why it matters

This functionality allows the system to absorb low-cost electricity whenever it’s available, without interrupting heat delivery. It effectively decouples charging from discharging, insulating operations from power market volatility.

In short, Heatcube acts as a 3-in-1 system: it consumes electricity, converts it into Thermal Energy, and delivers heat — all on demand 24/7.

Balancing the grid

Heatcube's certified fast ramp-up time enables it to act as a balancing asset for the grid and participate across all reserve markets. By adjusting operations in response to grid signals, Heatcube contributes to system stability and helps mitigate supply–demand imbalances.

Balancing via Heat-as-a-Service

Through our Heat-as-a-Service model, Heatcube's system is programed to respond to price signals and ancillary service calls — optimizing when and how process heat is produced to align with both customer demand and grid needs.

This approach ensures stable heat supply while enabling the asset to generate additional value through market participation — all without placing any operational burden on the end user.

-

2020

PILOT

Technology verification and transformed to test site for R&D.

-

2021

FIRST GENERATION HEATCUBE

Pilot commercial installation at Norbis Park, Denmark.

-

2022

SECOND GENERATION HEATCUBE

Commercial installation at KALL Ingredients, Hungary.

We are proud of the smooth and successful introduction of the world’s largest electrical heater for molten salt and are looking forward to the large-scale commercial roll-out of Heatcube as well as the further development of the technology together with Kyoto Group.

Christopher Molnar, Managing Director of Vulcanic, a Spirax Sarco company

It is exciting to work together with the young and dynamic team of Kyoto and you can really feel the energy and the eagerness of the entire project team to contribute to a greener future. It gives me personally extra motivation for the entire project.

Magne Ryholt, Høglund Project Manager

Kyoto Group is addressing a crucial question on the agenda here in Germany and internationally: How to supply consistent industrial heat based on intermittent renewable energy sources instead of fossil fuels. We believe Heatcube is a very attractive answer to this question, and we very much look forward to working with Kyoto to realize its full potential.

Lutz Brandau, VP Sales of Steinmüller Engineering.

The partnership with Kyoto and its Heatcube thermal storage solution is a further step for Iberdrola in its mission to decarbonize the economy through electrification. Storage is one of the major challenges in the energy transition, hence this collaboration with the Norwegian group will be key to our strategy

Fernando Mateo, Global Head of Industrial Decarbonization at Iberdrola

Research & reports

/06%20Career/6.1%20Images/Career_Kyoto%20Group%200018.png)

Tech center

SEVILLA, SPAIN

A center for development, operations and maintenance. Our team of engineers with extensive experience in steam generation and molten salt, work to continuously develop our technology and supply an increasing demand for Thermal Energy in Europe.

R&D test center

HØNEFOSS, NORWAY

Home of our pilot project. The pilot serves as base for future development and testing as we scale the capacity and load of Heatcube.

R&D partner

STOCKHOLM, SWEDEN

KTH Royal Institute of Technology is Kyoto's technical and strategic advisor in relation to the development of the next generation Heatcubes.

You've reached the bottom, but maybe not the end of your curiosity...

Now that you know how the technology works, take a closer look at

the product it powers. Explore Heatcube

/01%20Homepage/1.6%20Partners%20logos/Yara@2x.png?width=112&height=112&name=Yara@2x.png)

/01%20Homepage/1.6%20Partners%20logos/RPOW@2x.png?width=112&height=112&name=RPOW@2x.png)

/01%20Homepage/1.6%20Partners%20logos/Aalborg-Forsyning@2x.png?width=112&height=112&name=Aalborg-Forsyning@2x.png)

/01%20Homepage/1.6%20Partners%20logos/AACSP@2x.png?width=112&height=112&name=AACSP@2x.png)

/01%20Homepage/1.6%20Partners%20logos/KTH@2x.png?width=112&height=112&name=KTH@2x.png)

/01%20Homepage/1.6%20Partners%20logos/Vulcanic.jpg?width=112&height=112&name=Vulcanic.jpg)

/01%20Homepage/1.6%20Partners%20logos/Cognite_logo_grey.png?width=112&height=112&name=Cognite_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/Energiaborze_logo_grey.png?width=112&height=112&name=Energiaborze_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/KALL%20Ingredients_grey.png?width=112&height=112&name=KALL%20Ingredients_grey.png)

/01%20Homepage/1.6%20Partners%20logos/Kyotherm_300.png?width=112&height=112&name=Kyotherm_300.png)

/01%20Homepage/1.6%20Partners%20logos/steinmueller_engineering_company_logo_300.png?width=112&height=112&name=steinmueller_engineering_company_logo_300.png)