PHARMACEUTICALS:

Your path to a sustainable

pharmaceutical industry

Get clean, cost-effective process heat for pharmaceutical manufacturing with Kyoto's Heatcube

/01%20Homepage/1.6%20Partners%20logos/Yara@2x.png?width=112&height=112&name=Yara@2x.png)

/01%20Homepage/1.6%20Partners%20logos/RPOW@2x.png?width=112&height=112&name=RPOW@2x.png)

/01%20Homepage/1.6%20Partners%20logos/Aalborg-Forsyning@2x.png?width=112&height=112&name=Aalborg-Forsyning@2x.png)

/01%20Homepage/1.6%20Partners%20logos/AACSP@2x.png?width=112&height=112&name=AACSP@2x.png)

/01%20Homepage/1.6%20Partners%20logos/KTH@2x.png?width=112&height=112&name=KTH@2x.png)

/01%20Homepage/1.6%20Partners%20logos/Vulcanic.jpg?width=112&height=112&name=Vulcanic.jpg)

/01%20Homepage/1.6%20Partners%20logos/Cognite_logo_grey.png?width=112&height=112&name=Cognite_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/Energiaborze_logo_grey.png?width=112&height=112&name=Energiaborze_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/KALL%20Ingredients_grey.png?width=112&height=112&name=KALL%20Ingredients_grey.png)

/01%20Homepage/1.6%20Partners%20logos/Kyotherm_300.png?width=112&height=112&name=Kyotherm_300.png)

/01%20Homepage/1.6%20Partners%20logos/steinmueller_engineering_company_logo_300.png?width=112&height=112&name=steinmueller_engineering_company_logo_300.png)

Cut emissions and costs without disrupting operations

The pharmaceutical industry is at a crossroads.

With 4.4% of global greenhouse gas emissions — 55% more carbon-intensive than the automotive sector — pharmaceutical manufacturing is under pressure to act. From sterilization to temperature-controlled logistics, the industry is built on energy-intensive processes that rely heavily on fossil fuels. Without urgent intervention, rising costs, stricter regulations, and growing ESG demands will threaten operational stability and profitability.

Yet, integrating sustainable energy solutions into existing processes is a significant challenge.

This is where Kyoto Group’s Heatcube enters the equation: Our thermal storage solution replaces fossil fuel boilers with clean, high-temperature process heat—offering a seamless, cost-effective transition to renewable energy. Choose between owning a Heatcube or Heat-as-a-Service (HaaS) for clean steam on demand — both tailored to your business and budget.

Partnering with Kyoto Group turns sustainability into a business asset.

Meet sustainabiliy goals

Heatcube helps pharmaceutical manufacturers cut emissions by replacing fossil-fueled heat with renewable thermal energy. Companies can reduce their carbon footprint by up to 14,000 tons annually while meeting global ESG standards.

Stabilize energy costs

By using Heatcube, pharmaceutical manufacturers can tap into off-peak renewable electricity, stabilizing energy costs and reducing exposure to volatile fossil fuel markets and carbon taxes — all while ensuring a dependable heat supply.

Turn sustainability into revenue

With Heatcube, manufacturers can generate extra revenue by supporting grid stability through demand response services — turning sustainability into a financial advantage. Kyoto Group’s experts help you maximize these revenue opportunities.

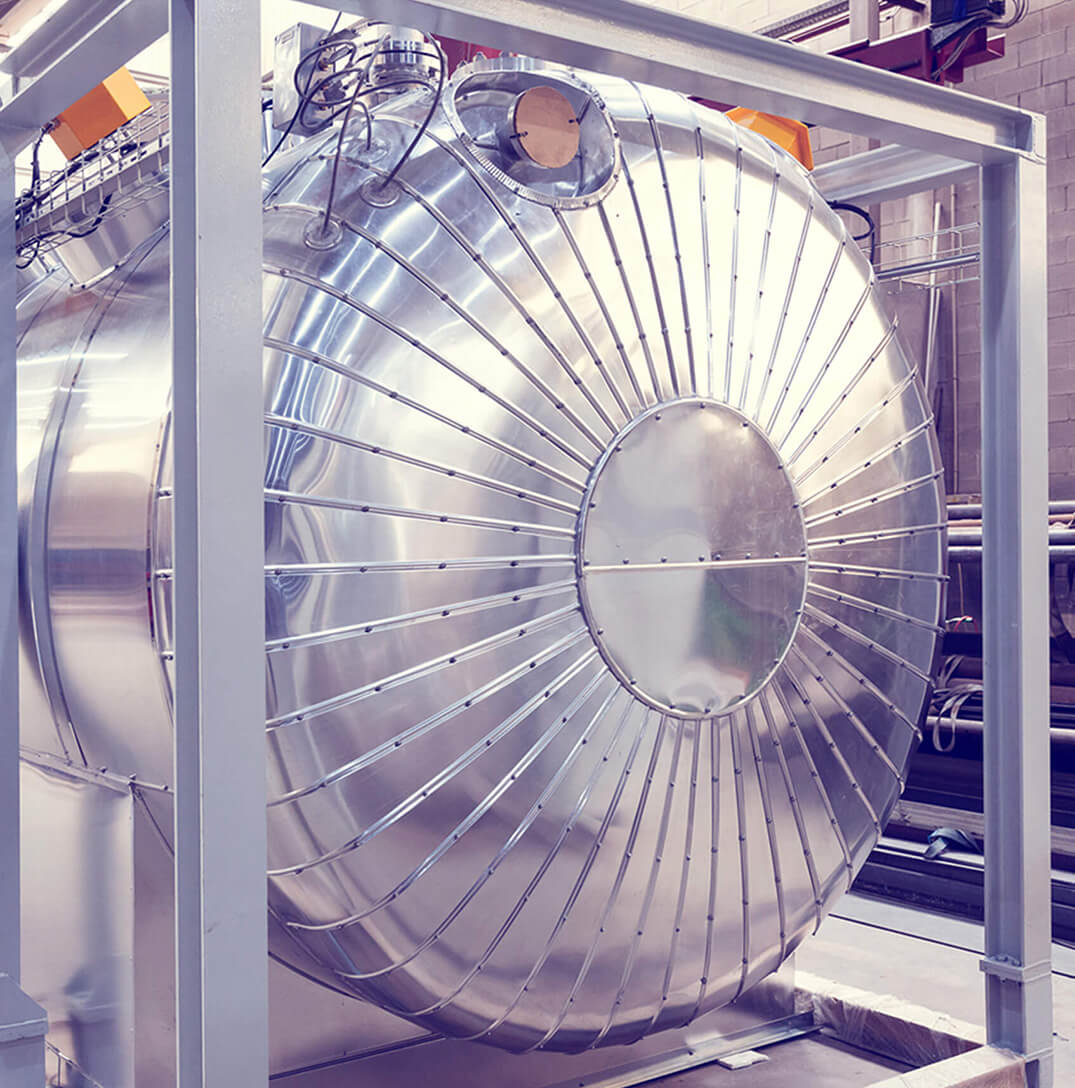

Heatcube: Proven and working

Heatcube is a thermal battery delivering high-temperature clean process heat for industrial processes, replacing fossil fuels with renewable energy. The tech is already operational, providing reliable heat in real-world settings. Designed to integrate seamlessly into existing systems, it offers a tested, cost-effective solution for industries looking to cut emissions and stabilize energy costs.

Here’s how Heatcube works

Heatcube stores energy from renewable sources like wind and solar during off-peak, low-cost hours. Molten salt is heated by multiple renewable sources to over 415°C to release high-temperature heat (steam) on demand, ensuring a consistent and sustainable energy supply.

Heatcube in action: A cross-industry solution

In Hungary, KALL Ingredients is decarbonizing and advancing starch production with Kyoto Group’s Heatcube. This project, now nearing completion, is set to replace fossil fuels with clean, renewable heat—cutting emissions by up to 8,000 tons of CO₂ annually, stabilizing energy costs, acting as a balancing asset for the electrical grid and proving that industrial decarbonization is not just a concept, but a tangible reality.

Expert insight

What’s the real cost of a donut?

In the food and beverages industry, every product has a hidden price tag: fossil fuels. In How to Decarbonize a Donut, Kyoto’s Lars Martinussen shows how cutting emissions with Heatcube isn’t just smart—it’s also a sassy, profitable business move. And the best part? It’s not just for the food and beverages industry — it’s also applicable to pharmaceuticals.

White paper

The nitty-gritty of Heatcube

Curious how thermal energy storage transforms energy strategy? In our whitepaper, discover how Heatcube stores renewable energy, cuts costs, and slashes emissions—all while boosting industrial efficiency.

Hassle-free heat

Heat as a Service (HaaS)

Access clean, renewable heat with minimal upfront investment. Kyoto Group takes care of installation, operation, and maintenance while you simply purchase heat as you need it. This turnkey solution eliminates financial barriers and simplifies the transition to sustainable energy for your pharmaceutical company.

Operated by Kyoto

All HaaS solutions are managed by Kyoto Group, ensuring seamless operation and reliability. From energy storage to heat delivery, we handle every detail so you can focus on running your business efficiently.

Heat on your terms

Heat as a Product (HaaP)

With Heat as a Product (HaaP), you gain ownership of a Heatcube, allowing you to produce renewable heat on-site. This solution integrates into your operations, delivering high-temperature heat while cutting emissions and energy costs. By adopting this technology, you turn sustainability into a valuable business asset.

A sustainable investment

Owning a Heatcube is an investment in energy independence and long-term cost savings. It empowers your business to reduce reliance on fossil fuels, meet sustainability goals, and position itself as a leader in clean energy adoption.

Based on one cycle per day, the round trip efficiency from electricity to steam is minimum 93%.

Heatcube is equipped with a 20 MW steam generation system. The temperature and pressure do depend on the feed water supply and energy storage volume, but our standard configuration (64 MWh storage) delivers more than 12 hours of 7.5 tons per hour at 16 bar(a), with a feedwater temperature of 100°C (equals 5 MWh for 12 hours).

Heatcube is supplied with a Battery Management System (BMS), which can be connected with the local Energy Management System (EMS) using a standard industry interface. The storage tanks do not require any preventive or periodic maintenance. The auxiliary systems (pumps, valves, etc) require minimal ongoing maintenance and training will be provided.

For an industrial facility with steam demand covered by an electric boiler, the energy cost is directly related to the average and/or peak power prices in the region it is located. With Heatcube, we can offer significant energy savings by load-shifting the electricity demand from high-priced to low-priced hours in the power market.

The increasing share of intermittent renewable power production together with decommissioning of fossil-based power generation creates more price volatility in the power markets. In the hours with high wind and solar power output and low demand, the power prices become very low, while in hours with less wind and solar, the power prices are consequently very high. With Heatcube, we are utilizing the increasing price volatility in the power markets to store energy in hours with high renewable production and low prices. When charging Heatcube with cheap electricity from excess renewable power production, we can deliver renewable heat whenever needed at a very low cost. At the same time, we are replacing fossil fuels with renewable electricity as the energy source for heat production, and so removing close to all carbon emissions associated with the industrial heat demand.

Heatcube is designed with a steam temperature range from 135°C to 400°C and can generate up to 20MW of discharge capacity. The saturated steam temperature is between 135°C and 212°C, with a steam pressure between 8 and 20 bar(a). To achieve 400°C with a pressure 3 - 40 bar(a) (superheated steam) a superheater can be added to Heatcube steam generator.

Connect with Kyoto

And discover the benefits of the Heatcube.

Please provide your contact information

So that we can start the conversation